Background

Hemp is a distinct variety of the plant species Cannabis sativa L. that grows to a height anywhere from 4-15 ft (1.2-4.5 m) and up to 0.75 in (2 cm) in diameter. The plant consists of an inner layer called the pith surrounded by woody core fiber, which is often referred as hurds. Bast fibers form the outer layer. The primary bast fiber is attached to the core fiber by pectin—a glue-like substance. The primary fibers are used for textiles, cordage, and fine paper products. The wood-like core fiber is used for animal bedding, garden mulch, fuel, and an assortment of building materials.

Due to the similar leaf shape, hemp is frequently confused with marijuana, another cannabis plant. The major difference is their tetrahydrocannabinol (THC) content, the ingredient that produces the high when smoked. Marijuana can contain as much as 20% THC, compared to less than 1% for industrial hemp. Despite this difference, some countries are reluctant to legalize growing of hemp (especially the United States), since there is a fear this will make it more difficult to control the use of the drug. Most hemp varieties also have a hollow stalk that have a very high fiber content (35%), in contrast to marijuana varieties that usually have a solid stalk having low fiber content (15%).

Canada is one country that has legalized hemp, though with certain restrictions. The maximum allowable THC concentration is 0.3% and all hemp farmers are required to undergo a criminal-records check, as well as obtain a license from Health Canada. Despite these restrictions, hemp production has increased threefold in just a year, from 6, 175 acres (61.75 hectares) harvested in 1998 to nearly 20,000 acres (200 hectares) in 1999. Over 95% of the acres grown in 1999 in Canada were for hemp grain.

Farmers who grow hemp claim it is a great rotation crop and can be substituted for almost any harvest. It grows without requiring pesticides and is good at aerating the soil. On a per-acre basis, one estimate claims hemp nets farmers more income ($250-$300) than either corn or soybeans ($100-$200). A full crop of hemp only takes 90 days to grow, yielding four times more paper per acre, when compared over a similar 20 year period with redwood trees in the northwest United States. However, there are other varieties of trees that yield two to three times more than hemp.

Advocates of hemp claim that it can be used in 25,000 different products, from clothing to food to toiletries. Until the nineteenth century, hemp was used in 90% of ships’ canvas sails, rigging, and nets (and thus it was a required crop in the American colonies). Today, hemp fiber is being used as a replacement for fiberglass in automotive components and made into cloth for window dressings, shower curtains, and upholstery. China is the world’s largest producer of hemp fabric, whereas India produces the most hemp overall.

Other products made from hemp fiber include: insulation, particleboard, fiberboard, rope, twine, yarn, newsprint, cardboard, paper, horse stable bedding, and compost. Hemp bedding has been found superior to straw and other materials for horse stalls in reducing the smell of ammonia. Hemp seed is used to make methanol and heating oil, salad oil, pharmaceuticals, soaps, paint, and ink.https://googleads.g.doubleclick.net/pagead/ads?client=ca-pub-5788426211617053&output=html&h=600&slotname=4702241759&adk=1223421331&adf=3740447233&pi=t.ma~as.4702241759&w=180&fwrn=4&fwrnh=100&lmt=1625350106&rafmt=1&psa=0&format=180×600&url=http%3A%2F%2Fwww.madehow.com%2FVolume-6%2FIndustrial-Hemp.html&flash=0&fwr=0&rpe=1&resp_fmts=4&wgl=1&dt=1625350103402&bpp=3&bdt=1216&idt=2679&shv=r20210630&ptt=9&saldr=aa&abxe=1&prev_fmts=0x0%2C1162x280&nras=1&correlator=1590395403308&frm=20&pv=1&ga_vid=903676487.1625350106&ga_sid=1625350106&ga_hid=1894268836&ga_fc=0&u_tz=300&u_his=1&u_java=0&u_h=768&u_w=1366&u_ah=728&u_aw=1366&u_cd=24&u_nplug=3&u_nmime=4&adx=94&ady=1189&biw=1349&bih=657&scr_x=0&scr_y=0&eid=42530671%2C31060047%2C31061217&oid=3&pvsid=3183325692452306&pem=196&eae=0&fc=1920&brdim=0%2C0%2C0%2C0%2C1366%2C0%2C1366%2C728%2C1366%2C657&vis=1&rsz=%7C%7CeEbr%7C&abl=CS&pfx=0&fu=128&bc=23&ifi=3&uci=a!3&btvi=1&fsb=1&xpc=y58mawjdv7&p=http%3A//www.madehow.com&dtd=2689

Currently 32 countries, including Canada, Great Britain, France, and China, allow farmers to grow industrial hemp. The current hemp market for sales and exports in North America is estimated at between $50-$ 100 million per year. Unites States imports of industrial woven fabrics made from hemp totaled $2.9 million in 1997. Import volume jumps to around $40 million when other products—such as paper, shampoo, and oil—are included. Textile uses of hemp represent 5% of hemp products produced in Canada.

History

Hemp was the first plant to be domestically cultivated around 8000 B.C. in Mesopotamia (present-day Turkey). Hemp was grown for fiber and food. It was recorded as being harvested in central Asia around 6500 B.C. Several centuries later, China started growing hemp as a crop and later used it in medicine. By 2700 B.C. , the Middle East, Africa, and most of Asia used hemp for fabric, rope, medicine, and food. Hemp was introduced to Europe 400 years later. The oldest surviving piece of paper, a 100% Chinese hemp parchment, was dated to A.D. 770.

From 1000 B.C. to the nineteenth century, hemp was the world’s largest agricultural crop, where it was also used for paper and lamp oil. During this period, several well-known books, including the Bible and Alice in Wonderland, were printed on hemp paper, and several famous artists painted on hemp canvas. The first crop in North America was planted by a French botanist in Nova Scotia in 1606. Thomas Jefferson drafted the United States Declaration of Independence on hemp paper and grew hemp him-self. Two centuries later, the United States and Canada put a stop cannabis cultivation in 1937 with the Marijuana Tax Act (this put a one dollar per ounce tax on any hemp manufacturers), which was later lifted during the World War II effort.

Global production of hemp has been declining since the 1960s, from over 300,000 short tons (272,160 t) of hemp fiber and tow in 1961 to 69,000 short tons (62,597t) in 1997. China accounts for 36% of this production and 73% of grain production. This has dropped from 80,000 to 37, 000 short tons (72,576 to 33,566 t) over the same period. Around 1994, there were 23 paper mills using hemp fiber, at an estimated world production of 12,000 short tons (10,886 t) per year. Most of these mills were located in China and India for producing printing and writing paper. Others produced specialty papers, including cigarette paper. The average hemp pulp and paper mill produces around 5,000 short tons (4,536 t) per year, compared to wood pulp mills at 250,000 short tons (226,800t) per year.

However, in the last decade, the number of companies trading in and manufacturing hemp products has increased dramatically. The North America market is still in its infancy since Canada just legalized hemp production and sale in 1998. Hemp cultivation tests in the United States began a year later though it is still illegal to grow it commercially.

Raw Materials

Fiber processing uses few chemicals, if any at all. However, the fiber may be blended with other materials, such as synthetic fibers or resins as binders, depending on the final product being made. For paper making, water and chemicals (sodium hydroxide or sulfur compounds) are mixed with the fibers to remove the natural glue components.

The Manufacturing Process

Cultivation and harvesting

Hemp is an annual plant that grows from seed. It grows in a range of soils, but tends to grow best on land that produces high yields of corn. The soil must be well drained, rich in nitrogen, and non-acidic. Hemp prefers a mild climate, humid atmosphere, and a rainfall of at least 25-30 in (64-76 cm) per year. Soil temperatures must reach a minimum of 42-46°F (5.5-7.7°C) before seeds can be planted.

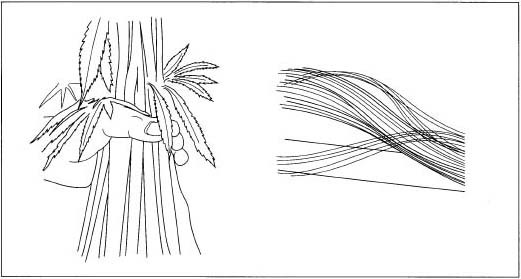

- 1 The crop is ready for harvesting high quality fiber when the plants begin to shed pollen, in mid-August for North America. Harvesting for seed occurs four to six weeks later. Fiber hemp is normally ready to harvest in 70-90 days after seeding. A special machine with rows of independent teeth and a chopper is used. To harvest hemp for textiles, specialized cutting equipment is required. Combines are used for harvesting

An example of hemp and hemp fibers.grain, which are modified to avoid machine parts being tangled up with bast fiber.

An example of hemp and hemp fibers.grain, which are modified to avoid machine parts being tangled up with bast fiber. - 2 Once the crop is cut, the stalks are allowed to rett (removal of the pectin [binder] by natural exposure to the environment) in the field for four to six weeks—depending on the weather—to loosen the fibers. While the stalks lay in the field, most of the nutrients extracted by the plant are returned to the soil as the leaves decompose. The stalks are turned several times using a special machine for even retting and then baled with existing hay harvesting equipment. Bales are stored in dry places, including sheds, barns, or other covered storage. The moisture content of hemp stalks should not exceed 15%. When planted for fiber, yields range from 2-6 short tons (1.8-5.4t) of dry stalks per acre, or from 3-5 short tons (2.7-4.5 t) of baled hemp stalks per acre in Canada.

Grain processing

- 3 Hemp seeds must be properly cleaned and dried before storing. Extraction of oil usually takes place using a mechanical expeller press under a nitrogen atmosphere, otherwise known as mechanical cold pressing. Protection from oxygen, light, and heat is critical for producing a tasty oil with an acceptable shelf-life. Solvent extraction methods are also emerging for removing oil since they achieve higher yields. Such methods use hexan, liquid carbon dioxide, or ethanol as the solvent. Refining and deodorizing steps may be required for cosmetics manufacturers.

- 4 A dehulling step, which removes the crunchy skin from the seed using a crushing machine, may be required. Modifications to existing equipment may be required to adequately clean the seeds of hull residues.

Fiber processing

- 5 To separate the woody core from the bast fiber, a sequence of rollers (breakers) or a hammermill are used. The bast fiber is then cleaned and carded to the desired core content and fineness, sometimes followed by cutting to size and baling. After cleaning and carding, secondary steps are often required. These include matting for the production of non-woven mats and fleeces, pulping (the breakdown of fiber bundles by chemical and physical methods to produce fibers for paper making), and steam explosion, a chemical removal of the natural binders to produce a weavable fiber. Complete processing lines for fiber hemp have outputs ranging from 2-8 short tons/hour (1.8-7.2 t/hr).

Packaging

- 6 The primary fiber is pressed into a highly compressed bale, similar to other fibers like cotton, wool, and polyester. Other products, such as horse bedding, are packaged in a compressed bale.

Paper making

- 7 Bast fibers are usually used in paper, which are put into a spherical tank called a digester with water and chemicals. This mixture is heated for up to eight hours at elevated temperature and pressure until all fibers are separated from each other. Washing with excess water removes the chemicals and the extracted binding components (pectin). The clean fibers are then fed into a machine called a Hollander beater, which consists of a large tub equipped with a wheel revolving around a horizontal axis. This beating step, which lasts for up to 12 hours, cuts the fibers to the desired length and produces the required surface roughness for proper bonding. Bleaching chemicals are sometimes added during this step or to separate tanks with the fibers. The bleached pulp is then pumped to the paper machine or pressed to a dryness suitable for transportation to a paper mill at another location.

Quality Control

Hemp fibers are tested for tensile strength, fineness (fiber diameter), and the color is recorded. Moisture content is recorded during every stage of the growing and production process. The THC content of the plant is also contiguously tested to make sure that the level does not exceed the 0.3% mark. Research is still being conducted on the effects that hemp would have on the industry. Set standards are constantly being altered and changed.

Byproducts/Waste

The harvested hemp not used is burned. During fiber processing, the core fiber is saved and usually used to make paper, horse bedding, or construction materials. Most hemp producers recycle the core fiber by removing dust, then baling and packaging. The dust can be pressed into pellets used for fuel. The dirt and small chips of core are also used as a high nutrient soil additive.

The Future

Where it is legal, the hemp industry has been growing at an annual growth rate of 20%. Other potential uses are being developed. For instance, hemp meal has demonstrated it can be used as a food ingredient for aquiculture farms, specifically freshwater fish and shrimp. Even hemp beer has entered the Canadian market, though it is expected to remain a small part of beer sales. Composite materials for the building industry are also being investigated.

Using hemp as a source of food may become the largest application, since hemp seeds have much nutritional value. The seed contains essential fatty acids, protein, calcium, iron, zinc, and vitamins B, C, and E. Hemp seed can be made into oil or flour and can also be eaten whole, since it tastes similar to pine nuts or sunflower seeds.

The outlook for hemp in the United States is uncertain since it is still illegal to grow it. There are 10 states that passed legislation in 1998 to allow growing hemp for research purposes—Arkansas, California, Hawaii, Illinois, Minnesota, Montana, New Mexico, North Dakota, and Virginia—and a number of other states are considering it. However, federal law still prohibits growing industrial hemp. The Drug Enforcement Agency will have to change its mind before any market can be developed in the United States. Once that happens, hemp could become a billion dollar crop if there is enough investment and interest, prices are competitive, and high quality products can be made. Processing technology also needs to be upgraded for higher value-added products.

Where to Learn More

Books

Schreiber, Gisela.The Hemp Handbook. Munich, Germany: Wilhelm Heyne Verlag GMBH & Co. KG, 1997.

Periodicals

Adams, John. “Dope Idea: U. Minnesota Could Research Uses of Industrial Hemp.” Minnesota Daily (March 30, 1999).

Anonymous. “Ag Study: Market for Hemp is Thin.” Dese Moines Register (January 30, 2000).

Kane, Mari. “Hemp Industry Prepares to Grow.” In Business (November/December 1999).

Katz, Helena. “Smoking Out New Hemp Markets.” Marketing (November 22,1999).

Nickson, Carole. “All-purpose Hemp a Retail Find.” Home Textiles Today (November 15, 1999).

Sturgeon, Jeff. “Hemp-Gooods Shop Capitalizes on Plant’s Versatility.” The Roanoke Times (August 8, 1999).

von Roekel, Jr., Gertjan. “Hemp Pulp and Paper Production.” ATO-DLO Agrotechnology (1994).

von Steinberg, Bob. “In Canada, hemp hasn’t lived up to the hype.” Star Tribune (October 16, 1999).

Ward, Joe. “Hemp Advocates Assail U.S. Report.”Courier-Journal (January 26, 2000).

Other

Geofrey G. Kime, President, Hempline Inc. 11157 Longwoods Rd., Delaware, Ontario, Canada, NOL lEO. (519) 652-0440. http://www.hempline.com . info@hempline.com.

North American Industrial Hemp Council, P.O. Box 259329, Madison, WI 53725-9329. (608) 258-0243. http://www.naihc.org . info@naihc.org.

Peter Dragla. A Maritime Industrial Hemp Product Marketing Study. Canadian Department of Agriculture and Marketing, 1999. http://agri.gov.ns.ca/pt/agron/hemp/hemp-masaf.htm (January 2001).

— Laurel M. Sheppard

Read more: http://www.madehow.com/Volume-6/Industrial-Hemp.html#ixzz6zayBOawF